Description

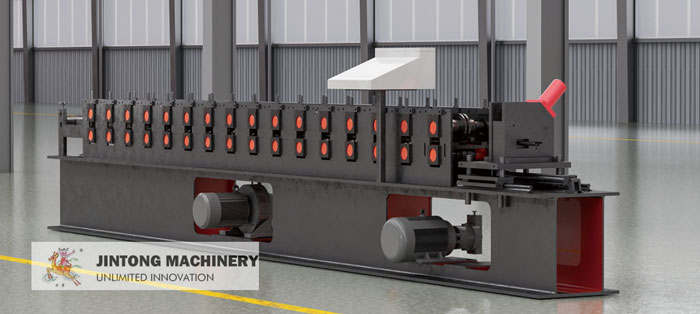

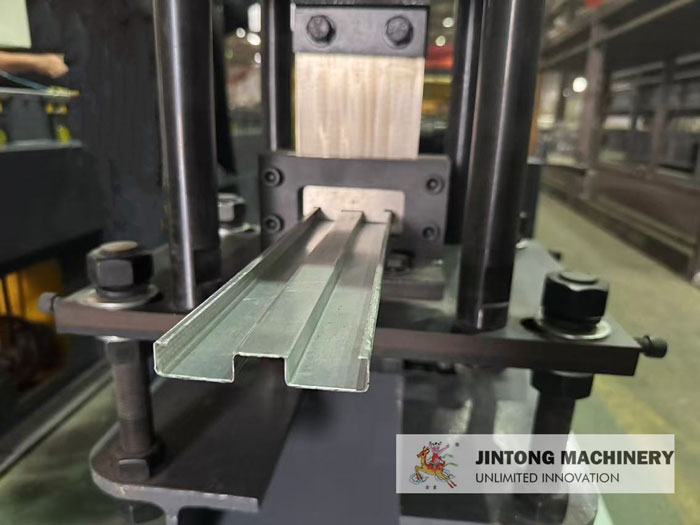

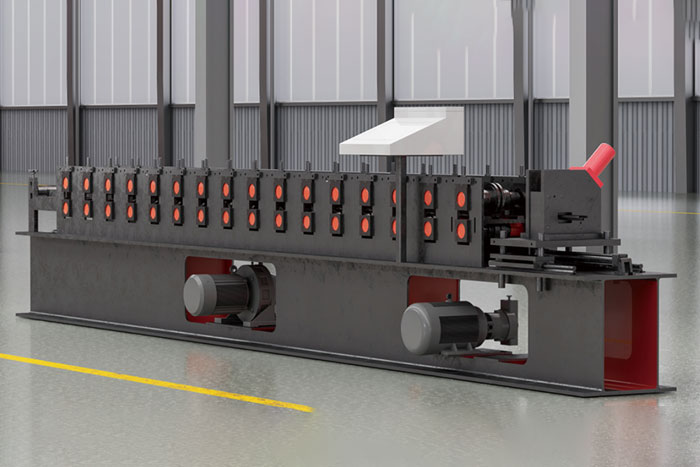

Clean Room Panel Drywall Frame Roll Forming Machine is specialized designed to produce drywall frames for clean room panel (also called clean room wall panels), which is a specialized building material used in the construction of clean rooms.This clean room drywall roll forming machine is composed of decoiler, main forming machine, hydraulic cutting machine, outer table, hydraulic system, PLC control system, etc. It can produce different clean room drywall frame size such as 50mm, 75mm, 100mm, or any other sizes as per customers’ requirement. Fully automatically controlled by PLC control system, this clean room panel drywall frame roll forming machine has the advantage of easy operation and fast efficiency.

Application

Clean room panel is a specialized building material used in the construction of clean rooms, which are controlled environments with low levels of airborne particles and contaminants. These panels are designed to meet the stringent requirements for cleanliness, air quality, temperature control, and particle filtration in industries like pharmaceuticals, biotechnology, electronics, and food manufacturing.

Clean room panels typically have the following characteristics:

1. Smooth, non-porous surface: this prevents dust, dirt, and contaminants from adhering to the surface, making it easier to maintain cleanliness.

2. Insulation: clean room panels often contain insulation materials like rock wool, mineral core, magnesium oxide board, aluminum honeycomb, etc for temperature control and to prevent condensation.

3. Durability: The outer surface of the clean room panels are made from strong, corrosion-resistant materials, such as stainless steel, galvanized steel, or specialized coated surfaces, to withstand rigorous cleaning and maintenance.

4. Sealed edges: the edges of clean room panels are often sealed to prevent the infiltration of particles or air leaks that could compromise the cleanliness of the room.

5. Fire-resistant properties: Many clean room panels are fire-rated to meet safety regulations.These panels are modular and can be easily assembled and disassembled, providing flexibility in designing and maintaining clean room spaces.

Working Process

Operation Flow:

3T Decoiler- main forming machine- hydraulic cutting – outer table

We are professional manufacturer of clean room panel roll forming machines for more than 30 years, in China, about 90% of the clean room panel manufacturers use our machines. The advantage of using clean room panel machine include high efficiency ( that you just need set the product length and quantity on touch screen, then the machine will run automatically), consistent product quality, and the ability to produce long lengths of channel without joints. These characteristics are essential for the structural integrity and durability of clean room panel systems.

Technical Specification

| Clean Room Panel Drywall Frame Roll Forming Machine | ||

| No. | Item | Specification |

| 1 | Suitable material | Galvanized Coil, PPGI, Stainless steel |

| Thickness(mm):0.4-0.8 | ||

| Yield strength: 250 – 550MPa | ||

| Tensil stress( Mpa):G350Mpa-G550Mpa | ||

| 2 | Nominal forming speed(m/min) | 0-15 |

| 3 | Forming station | 15 stations |

| 4 | Decoiler | 2 ton decoiler |

| 5 | PLC brand | Mitsubishi |

| 6 | Inverter brand | Delta/ ABB |

| 7 | Driving system | By chain |

| 8 | Rollers’ material | 45# steel |

| 11 | Power supply | 380V 50Hz 3PH |

| 12 | Machine color | Industrial blue |

Q & A

1. Q: What kinds of experience do you have in producing clean room panel drywall frame roll forming machine ?

A: We have rich experience of producing clean room panel drywall frame roll forming machines, till now more than 1500 sets clean room panel drywall frame roll forming machines produced and sold to customers local China and all over the world.

2. Q: What is delivery time of clean room panel drywall frame roll forming machine?

A: 60 days after contract confirmation.

3. Q: What is your machine production speed?

A: The machine running speed is 15m/min.

4. Q: What is your after-sales service system?

A: We will send engineer to customer’s factory for machine installation and commissioning, if customer require. We provide whole life service, If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

Machine Photo