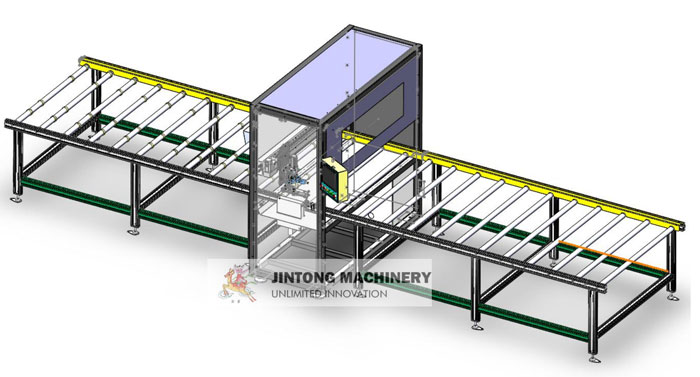

Description

This glue spraying machine for clean room panel production is a specialized piece of equipment used to apply adhesive precisely and efficiently during the manufacturing process of clean room panels. These panels, typically used in pharmaceutical, electronics, and semiconductor industries, require high-precision bonding to maintain airtight, contamination-free environments.

Functions of Glue Spraying Machine in Clean Room Panel Production

1. Adhesive Application – Evenly applies adhesive (such as PUR, PU, or epoxy) onto panel surfaces for secure bonding.

2. Automated Control – Ensures consistent glue application, reducing waste and improving efficiency.

3. High Precision – Maintains clean and uniform adhesive distribution to avoid contamination.

4. Temperature & Pressure Control – Some machines regulate adhesive temperature and pressure to optimize bonding strength.

5. Integration with Panel Assembly – Often works in tandem with press machines to complete the bonding process.

Advantage of this Glue Spraying Machine

1. Automatic edge recognition: it can automatically adjusts the glue spraying position according to the clean room panel size and length.

2. Automatic glue amount: automatically adjusts the speed of the glue dispensing accordingly to the clean room panel size and conveying speed.

3. Automatic glue feeding: when the glue volume in the glue barrel is lower than the set limit, the machine will add the glue automatically.

4. Glue heating: equipped with glue heating and heat preservation functions, the glue is not restricted by ambient temperature and region, allowing customers to choose the brand of glue more freely.

5. Auto cleaning : this glue machine adopts a high-pressure gas-liquid automatic cleaning device. There is no need to disassemble the glue spray head, and the machine can clean automatically itself.

6. Special metering pump: the equipment adopts a special polyurethane high-flow and ware-resistant precision metering pump, which can accurately control glue and adjust the flow rate to achieve an accuracy of ±0.5%, effectively avoiding inaccurate proportions and greatly improving the product qualification rate.

Application

This Glue Spraying Machine is widely used in different sandwich panel production, such as EPS sandwich panel, honey comb sandwich panel, insulation panel, composite sandwich panel, clean room panel, etc. Inside sandwich panel core material can be rock wool, EPS, honeycomb, aluminimum foam, fiberglass foam, etc, and outer surface material can be galvanized steel, color steel, stainless steel.

Technical Specification

| Glue Spraying machine | ||

| No. | Item | Specification |

| 1 | Power supply | 380V 50HZ ( as per requirement) |

| 2 | Pneumatic | 0.5MPa-0.8MPa |

| 3 | Equipment power | 2600W |

| 4 | Gluing speed | 0.5g-40g/sec |

| 5 | Proportioning accuracy | 100g±1% |

| 6 | Measurement method | Industrial computer + Mitsubishi PLC + precision metering pump + precision glue control valve |

| 7 | Machine size | about 1900mm(L) x 600mm(W) x 2000mm( H) |

| 8 | Machine weight | 1.5 Tons |

Q & A

1. Q: What kinds of experience do you have in producing Glue Spraying Machine ?

A: We have rich experience of producing auto clean room panel machines, till now more than 1000 sets glue spraying machines produced and sold to customers local China and all over the world.

2. Q: What is delivery time of glue spraying machine ?

A: 50 days after contract confirmation.

3. Q: What is your after-sales service system?

A: We will send engineer to customer’s factory for machine installation and commissioning, if customer require. We provide whole life service, If there will be any quality problems caused by non-human factors, we will handle it immediately for you and we will be ready for you 7X24H. One purchase, lifetime care for you.

Machine Photo